Checkers inspect bulk production lots for consistency across quality, weave and colour.

The Trim department issues the relevant product accessories, after a check and count.

Manual pattern making is supplemented with CAD patterning to ensure a perfect garment fit.

Initial manual lay markers are compared with computer markers, and the best of both are used

Smaller garment “components” are cut with a band cutter for precision, then trimmed further

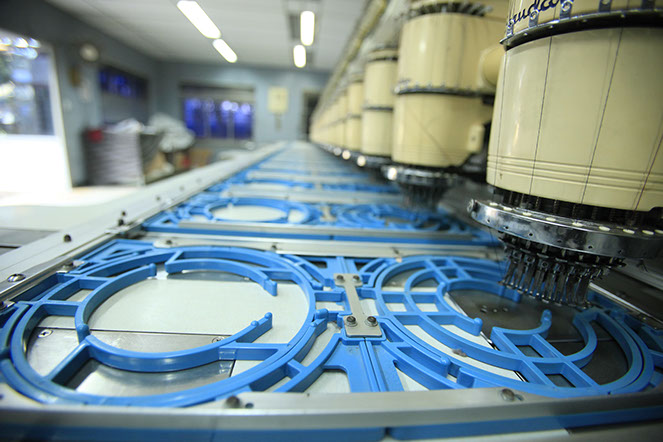

The computerised embroidery machines wait, ready for components to be embroidered.

Depending on the garment style and complexity, PSA has the option to allocate line assembly or full make up per machine.

Garments are inspected both in line and after production for any potential issues.

Tags and additional packaging are added onto the garments and packed as per customer's instructions

A final inspection ensures nothing has slipped by earlier checks. Standards for Inspection are guided by AQL stnadards.

10 - 10

<

>

Manufacturing -

Our factories, have a combined strength of 1000 machines for the production of garment made ups, scarves and home linen.

PSA currently employs over 1300 people.

Factories are equipped with machines from Brother and Juki, with an installed machine capacity of 1200.

Output garment capacity is 1.2 million made ups per year.

We are C-TPAT compliant, and SA-8000 certified.